The LycoVent is based on a 2010 design by the Massachusetts Institute of Technology for a low-cost portable ventilator suited to Low Middle Income Countries and for the strategic reserve in the US as a backup ICU ventilator. Improvements have been made to provide a more mechanically robust design and significantly improve the level of patient monitoring.

The LycoVent has five moving parts, a geared electric motor with an attached shaft encoder, two connecting rods and two pivoting arms with attached paddles. The reversing rotation of the motor is converted to an open / close motion of the paddles pressing on either side of a Teleflex BMV (Bag Mask Ventilator). The mechanics of the ventilator are explained in the video below.

Just five moving parts delivers controlled ventilation

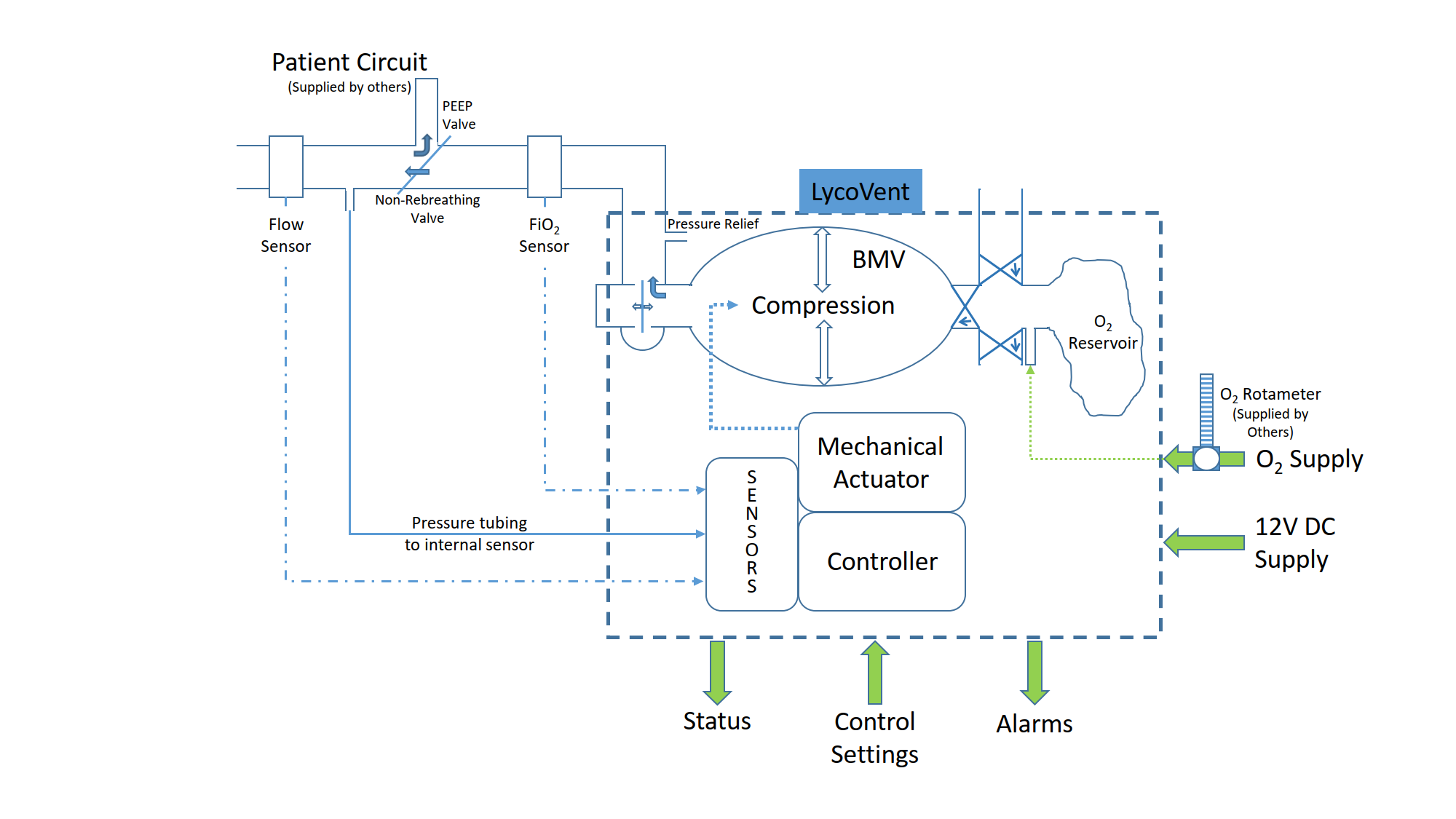

The reversing movement of the compression paddles is provided by a motor controller driven by the microprocessor that controls the degree of rotation, the speed of rotation and the rest periods of the gearbox output shaft. This allows the ventilator to deliver a range of Tidal Volume (TV), Respiration Rate (RR) and I:E ratios set by the clinician.

The control system is microprocessor-based using commonly available Arduino units. Clinical input is via a touch screen and a rotary encoder / push button. The processor has been programmed to provide the targeted volume using only the pressure sensor and information on the position of the arms provided by feedback from the encoder on the motor shaft.

A flow sensor in the breathing circuit is not part of the control system but reports the actual measured flow and is used for verification of delivery accuracy. The breathing circuit also includes an ultrasonic oxygen concentration sensor with information from the pressure, flow and oxygen sensors being displayed on screen. The microprocessor also monitors the system will generate alarms if operating parameters are out of range.